SCHOTT

2025

SCHOTT Suisse SA powers ESO’s most advanced telescope with cutting-edge infrared filters

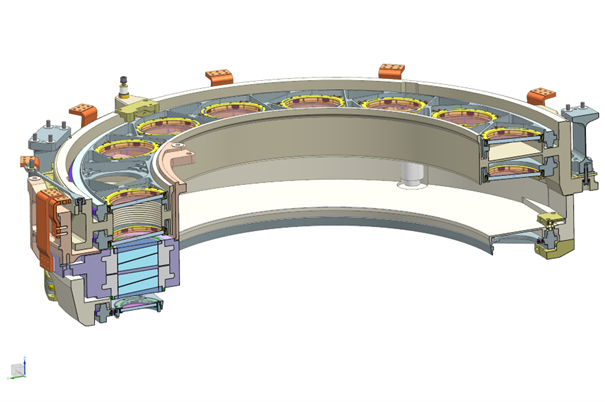

From its base in Yverdon-les-Bains, SCHOTT Suisse S.A.’s optical components division has been selected to supply 21 types of high-performance interference bandpass filters for the near-infrared (NIR) spectrum of the ESO Extremely Large telescope (ELT), covering wavelengths from 800 to 2500 nanometers. The MICADO instrument, in which the filters will be implemented, belongs to the first generation of instruments to be connected to the ELT telescope scheduled for scientific observation start in 2029. This achievement builds on SCHOTT’s long-standing legacy in precision interference coatings and its trusted role in supplying components for astronomical telescopes.

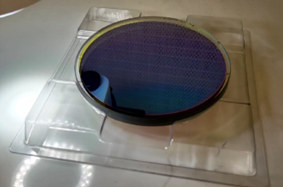

SCHOTT is applying advanced thin-film layers to infrared-grade fused silica substrates - meticulously polished in-house. These specialized coatings are designed to isolate specific NIR wavelength bands used in astronomical sky surveys, enabling scientists to peer deeper into the cosmos than ever before.

A Key Role in the MICADO Instrument

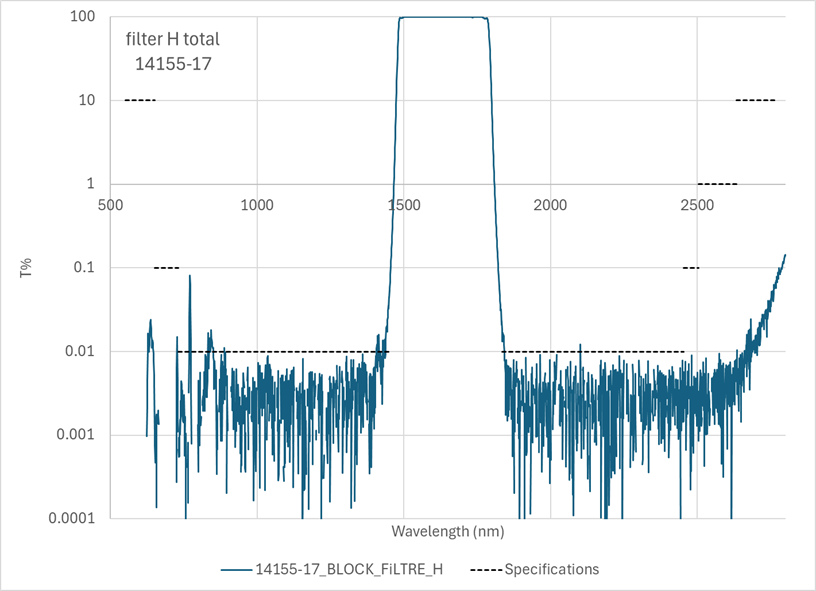

The filters target specific NIR bands—namely I, Y, J, H, and K—along with sub-bands within these ranges. These bands are crucial for detecting the redshift of celestial objects, a phenomenon caused by the expansion of the universe, the Doppler effect, and gravitational redshift. By analyzing redshift, astronomers can determine the age and distance of galaxies, essentially looking back in time to the era when most galaxies were forming.

Thanks to the ELT’s adaptive optics, which correct for atmospheric distortion, MICADO will be able to track the motion of stars just five light-days from the supermassive black hole at the center of our galaxy.

Engineering at cryogenic temperatures

Each filter is designed for cryogenic operation at 77 Kelvin (–196°C). They are tested under these extreme conditions to ensure optimal transmission and minimal wavefront distortion. The design also compensates for slight spectral shifts caused by differences in thermal expansion between the coating and substrate materials.

A highly precise manufacturing set-up

For the MICADO project, SCHOTT selected Plasma-Assisted Reactive Magnetron Sputtering (PARMS) - a highly stable and precise coating method. This technology allows for the deposition of up to 250 ultra-thin layers, totaling 50 microns in thickness, over a two-day process. Two PARMS machines at SCHOTT featuring load-lock systems and high-speed rotating substrate tables ensure uniform coatings with a variation of less than ±0.5% across substrates up to 300 mm.

The coating materials—typically niobium oxide, silicon oxide, and tantalum oxide—form dense, hard, and abrasion-resistant layers with near-bulk material properties. Real-time optical monitoring ensures each layer reaches its exact thickness, enabling the creation of complex, high-performance interference filters.

Collaboration Across Borders

SCHOTT works closely with ASTRON-NOVA in the Netherlands to fine-tune MICADO filters for cryogenic performance. Beyond MICADO, SCHOTT in Switzerland supplied advanced interference filters for the JPAS survey at CEFCA (Centro de Estudios de Física del Cosmos de Aragón) in Spain, enabling precise photometric mapping for cosmology. The SCHOTT Group also contributes to some of the world’s most ambitious telescope projects, providing ZERODUR® components for unmatched thermal stability and precision. These include the ESO Extremely Large Telescope (ELT) with its 39-meter segmented mirror, the Keck Observatory in Hawaii, Gran Telescopio Canarias, the Very Large Telescope (VLT), and the DKIST solar telescope.

About Schott Suisse SA

SCHOTT Suisse SA, based in Yverdon-les-Bains, is a subsidiary of the SCHOTT Group specializing in precision optics and advanced materials. The company manufactures and processes optical glass, ceramics, and other high-tech materials, producing polished and coated components as well as optical sub-assemblies for scientific, industrial, and aerospace applications. It serves as a key hub for engineering and distribution of SCHOTT’s innovative glass technologies in Switzerland.

Dr. Ulf Brauneck

Principal scientist Coating and Coated components

SCHOTT Suisse S.A.

Yverdon-les-Bains - Switzerland