ROLLVIS SA

2024

Geneva-based Rollvis SA turns the screw on wayward particles on the new High-Luminosity LHC collimators

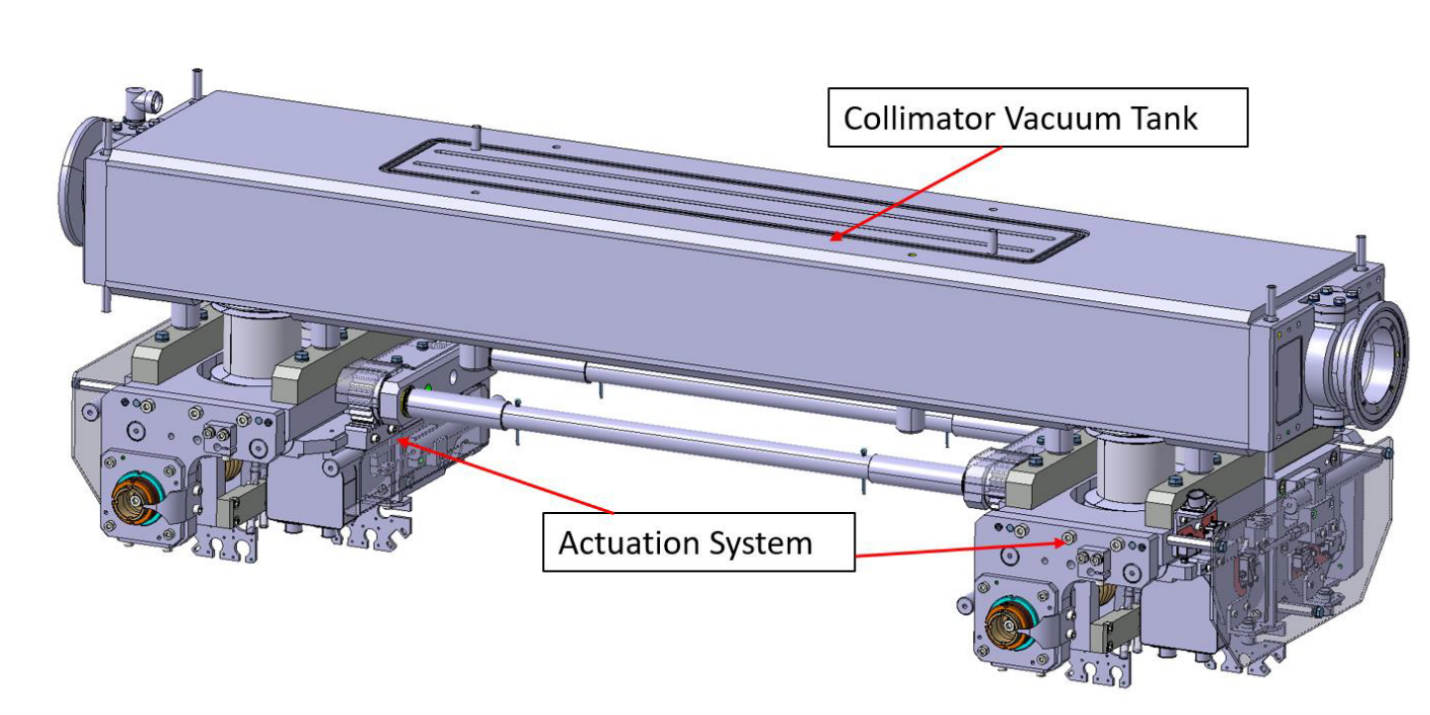

The beam intensity of the High-Luminosity LHC project is ten times higher than the original LHC, prompting the development of upgraded collimators to protect the accelerator. Particles that stray from the beam trajectory will be absorbed by thirty new, more efficient collimators. Roller screws from the Swiss company Rollvis SA that transform a rotational movement into a linear force come to play in the high-precision mechanical actuation system of the collimator.

A beam-cleaning process

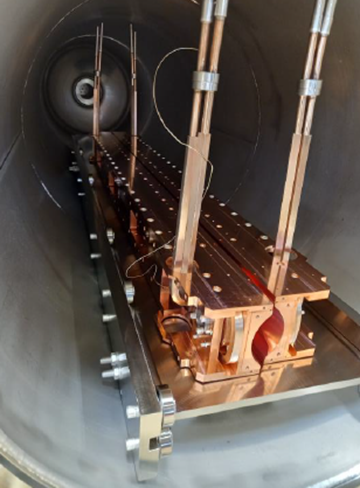

Not perceived as prestigious as other key components of the accelerator system, such as the bending and focusing magnets or the accelerating RF cavities, the collimators are crucial to the LHC ring. Each collimator is equipped with two jaws which absorb the beam halo, preventing diverging particles from disturbing the focused beam and so guaranteeing a high-quality beam before entering the physics experiments.

The jaw, engineered from solid metal alloy plates, must have an exact beam axis orientation and be aligned at a precise distance from the beam aperture to capture only the lost particles without interfering with the main beam.

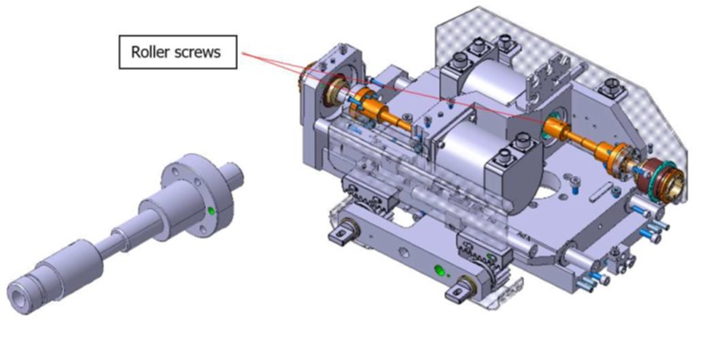

The core element of the mechanism that adjusts the position of the one-meter-long jaws with micrometer precision is Rollvis’ satellite screws. In a small volume, they recover the rotational movement provided by a stepper motor to push the shafts supporting the jaws back and forth. Each extremity of the jaws requires one actuation system, which also includes the roller screw, to allow the linear movement of the jaw during operation. In each collimator there are four actuation systems.

As the collimators operate in the LHC ultra-high vacuum, the actuation systems are connected to the jaws via the edge welded bellow and shaft, which act as interface between the vacuum environment and the atmospheric pressure.

The operating environment for collimators is extremely tough. They operate in ultra-high vacuum, require perfect flatness of the beam-absorbing elements. They must demonstrate excellent heat exchange properties, an ability to absorb thermal shocks, and high reliability of the translation systems. To comply with the last requirement, CERN chose Rollvis’ world-class roller screw products, which combine precise positioning, powerful mechanical strength transfer, high-speed conversion efficiency, robustness, and reliability.

Technical specification

The CERN specification requires an axial play inferior to 0.02 mm and a maximum 6.4 kN force to move back and forth the plates over 30’000 cycles. The torque versus position must be linear over the stroke. Torque oscillations must not exceed 0.05 N·m, in any observed time period. The maximum static torque shall be lower than 0.35 N·m and the maximum dynamic torque shall be lower than 0.8 N·m.

A further challenge for Rollvis was assessing the compatibility of the CERN-provided lubrication greases formulated to resist the LHC’s continuously high radiation environment. An irradiation campaign on lubricated roller screws was devised at CERN. The evolution of grease under irradiation, namely viscosity variations as a function of the total dose, was observed, resulting in the identification of a grease suitable for final use. Finally, to validate the satellite roller screw functionality, a longevity test was performed on a dedicated cycling bench, with final operating conditions (loads and integration scheme) over 20’000 cycles and under a 5 MGy radiation exposure.

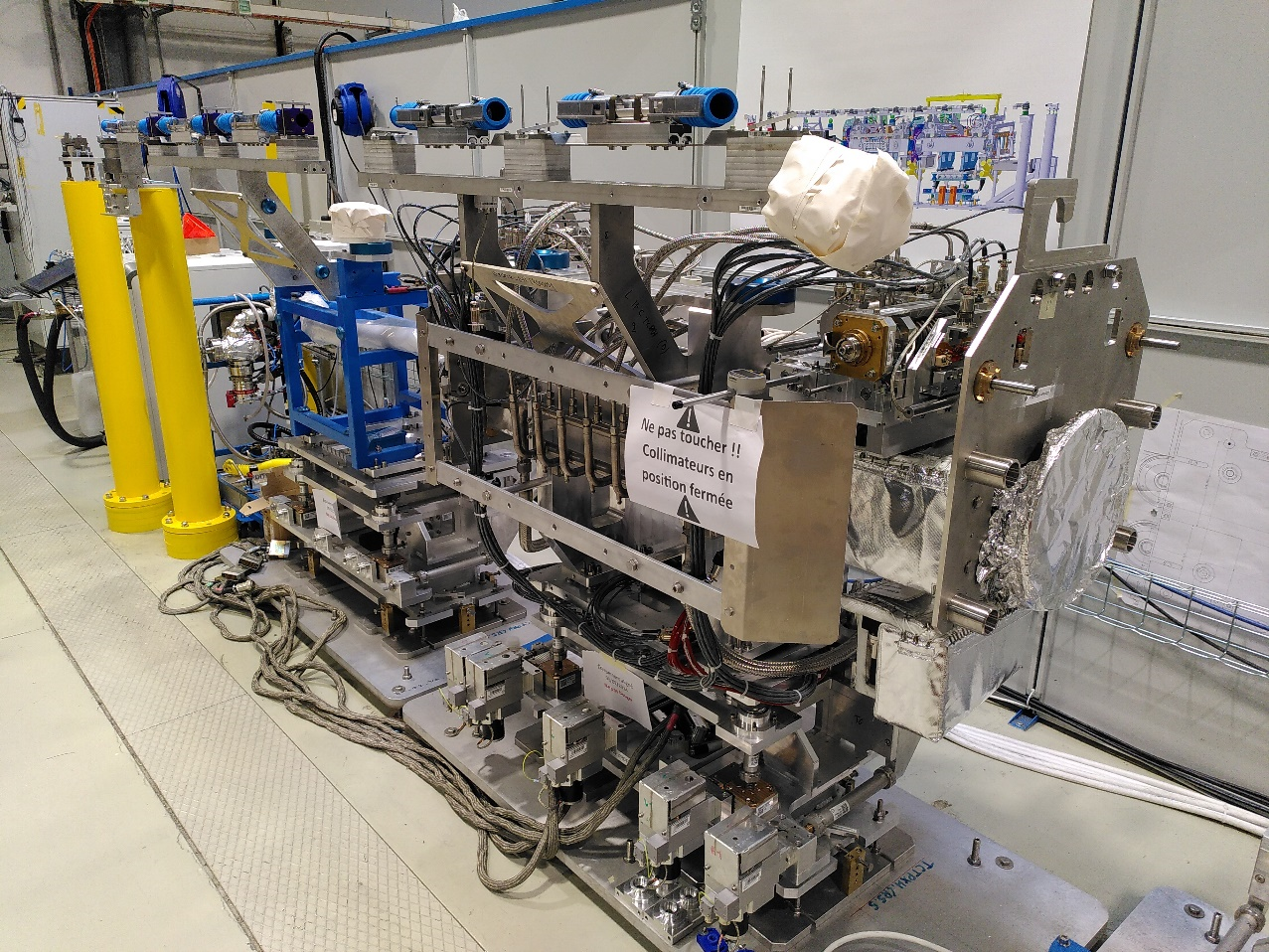

The upgraded HL-LHC collimation system comes with six different types of collimators, having either single or double-beam features. These variations however do not affect the Rollvis delivery. All the critical sub-components of the collimators (e.g., roller screws, UHV-compliant raw material, bellows, and absorbing blocks) are directly sourced by CERN. The UHV edge welded bellows are supplied by the Swiss Company COMVAT AG in Haag (SG), while the overall integration is entrusted to CINEL, an Italian company.

After several prototyping campaigns, notably for qualifying the appropriate grease specific to the LHC high radiation environment, Rollvis delivered to CERN in 2024 one hundred and twelve single-beam planetary roller screws. These will be installed on HL-LHC collimators in the tunnel during the next Long Shutdown LS3 2026-2028 and scheduled to operate in June 2030.

|

|

About Rollvis SA

The production of heavy-load satellite (or planetary) roller screws in Switzerland is associated with an engineering pedigree dating back to the time when train-locking systems were used to prevent the trains in the mountains from rolling back.

Rollvis SA was founded in Geneva in 1970 and today employs 70 people in Plan-Les-Ouates, the cradle of high-precision engineering in Geneva.

The company’s satellite roller screws have become the reference for high-precision linear motion applications. Rollvis has become the reference partner in the demanding domains of space, aeronautics, defense, energy, and the medical field. All design and critical manufacturing steps are performed in-house (final grinding, assembly, greasing, testing, and metrology).

Eliséo Bermejo

Senior Project Manager

Rollvis SA

Plan-Les-Ouates – Switzerland

bermejo[@]rollvis.com