Imbach & Cie AG

Imbach & Cie forge massive aluminium components with high precision for the CERN Large Hadron Collider

2018

The High-Luminosity Large Hadron Collider project at CERN, Geneva will enhance the performance of the flagship Large Hadron Collider accelerator to increase the potential for discoveries after 2025. The project will multiply the accelerator luminosity by a factor of five to allow experiments to gather more data and observe rare events. The project will also take the opportunity to replace many critical components of the accelerator which are reaching the end of their working life. An integral part of the upgrade are ten new Nb3Sn technology based superconducting magnets measuring 7 meters in length and providing peak magnetic fields of 11 tesla. Each magnet will be cooled to an operating temperature of 1.9 Kelvin (-271 ºC).

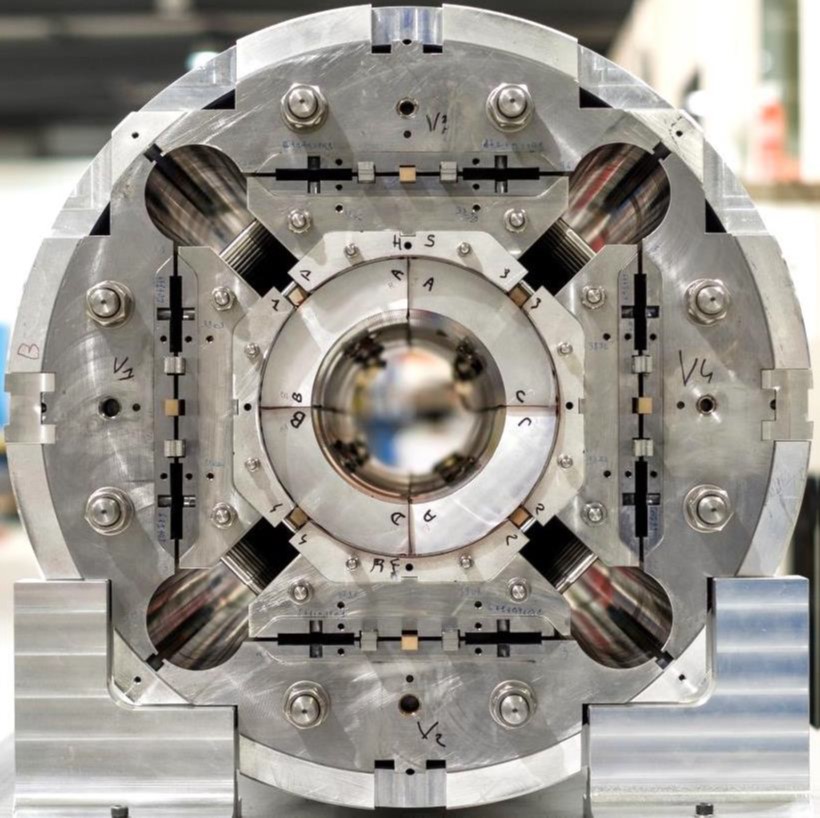

To withstand the significant mechanical stresses from cooling and the strong magnetic fields and high electrical currents during operation, each magnet is held together by cylindrical aluminium sleeves manufactured by Imbach. In order to avoid any distortions of the magnetic field, very narrow tolerances have to be achieved for the machined cylindrical sleeves.

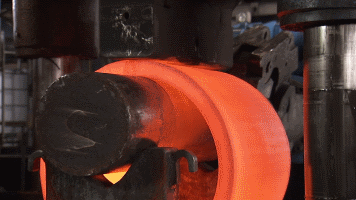

Starting from traditionnal forging technics

Imbach manufactured the magnet sleeves from a high-strength aluminium-zinc alloy. The forging blanks are manufactured by traditional open die forging using a hydraulic press.. The initial ring geometry is made by punching with a mandrel and stamping of a hole into the workpiece. CNC assisted ring rolling allows a constant reproducibility and usage of less additional material. Each cylindrical magnet sleeve is around 7 meters long, 0.63 meters in diameter and weighs around 200 kilograms.

The processes used by Imbach mean that the magnet sleeves can meet CERN’s exacting technical requirements of having no welding joints, optimum metallic grain flow, fine surfaces, high dimensional accuracy and outstanding mechanical properties. For CERN, Imbach plays a crucial role in meeting stringent quality requirements and successfully implementing new projects and the just-in-time delivery of the components helps in meeting the tight schedule for the project.

About IMBACH & Cie AG

Imbach & Cie AG is one of the leading forging companies in Switzerland. A family enterprise founded in 1889, Imbach is the only facility in Switzerland that can offer open die forging, ring rolling, drop forging, and complete machining, all under one roof. The company has extensive material experience in massive forming and cutting of all types of metals serving the application and development of new research instruments in the big science market. These include aluminium, stainless and acid resistant steels, creep resistant and high temperature steels, nickel-based alloys, titanium and copper alloys, and special materials such as pure iron, pure molybdenum and custom alloys.

The company employs approximately 90 people, whereof 12 apprentices in forging and machining department. Imbach is ISO 9001 and EN9100 (aerospace) certified and the company has a proven track record serving customers with high quality standards in the field of aviation industry, medical industry, power generation and distribution, transportation industry and process technology.

Martin Imbach

CEO

Imbach & Cie AG

Nebikon, Luzern, Switzerland

martin.imbach[@]imbach.com

www.imbach.com