2016

SwissNeutronics AG delivers Highly Brilliant Neutron Beams to ILL

SwissNeutronics is a leading supplier of neutron guide systems and neutron optical devices based on supermirror technology. Over the past 10 years, several hundred metres of supermirror neutron guide have been manufactured by SwissNeutronics and installed at the Institut Laue-Langevin in France as part of its refurbishment and development programmes. Using SwissNeutronics technology has delivered a factor x10 performance increase for the research instruments at the facility.

The Institut Laue-Langevin (ILL) in Grenoble, France first opened its doors to visiting scientists in 1972, and ever since then has been a leader in the field of neutron scattering science and technology. A key factor in this success has been the continuous renewal of the instruments and infrastructure. At the heart of the ILL, is a compact nuclear reactor producing intense beams of neutrons to study materials and obtain precise information about the position and the motion of the atomic structure. The fields of investigation range from technology applications to biology and health.

As space around the reactor is limited, neutron guide systems transport neutrons 20-150 metres away from the reactor core to locations where more space is available for instruments and experiment infrastructure. While the brightness of the ILL reactor is limited by technical reasons, modern supermirror neutron guides and advanced beam optics increase the efficiency of neutron transport from the reactor to deliver high brightness neutron beams to the instruments.

SwissNeutronics is a leading supplier of neutron guide systems and neutron optical devices based on supermirror technology and its products are highly regarded for their quality and high performance. Over the past 10 years, several hundred metres of supermirror neutron guide have been manufactured by SwissNeutronics and installed at the ILL as part of its refurbishment and development programmes.

Supermirrors

The supermirror neutron guides manufactured by SwissNeutronics are constructed by repeated deposition of thin film multilayers comprising alternating layers of two different materials, typically Ni/Ti and Fe/Si, involving a gradual variation of the layer thickness from about 2 nm to 100 nm.

An extremely low roughness of the substrates and the interfaces (s‹ 0.1 nm RMS) is a prerequisite to achieve a high supermirror reflectivity for neutron beams. Whilst supermirrors are traditionally coated onto glass substrates, SwissNeutronics has also developed a super-polishing process to refine the surface of metallic substrates for the coating of neutron supermirrors for highly reproducible large scale fabrication.

Refurbishment of the ILL neutron guide systems using SwissNeutronics technology has delivered a factor x10 performance increase for the ILL neutron instruments.

Large performance increase for neutron instruments

The next generation spallation source, the European Spallation Source (ESS), is currently under construction in Lund, in Southern Sweden. New technologies are employed to achieve the highest possible performance of the neutron instruments. Among those, substrates made from copper will be used as new material for neutron guides because of its excellent shielding properties for radiation. SwissNeutronics established super-polished copper substrates for supermirror neutron guides already in 2012.

In the past years SwissNeutronics manufactured complex supermirror guide elements for the specific neutron distribution requirements of a large variety of instruments at different facilities. Other developments, such as highly-efficient optics for polarized neutrons and the use of modern 3d metrology for the installation of the neutron guides, have also contributed to the enhanced performance of neutron scattering and imaging techniques.

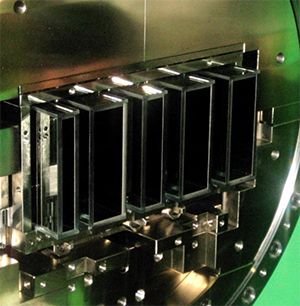

A Polarizing Neutron Guide at JRR-3M (Japan)

A Polarizing Neutron Guide at JRR-3M (Japan)An extremely low roughness of the substrates and the interfaces (s< 0.1 nm RMS) is a prerequisite to achieve a high supermirror reflectivity for neutron beams. Whilst supermirrors are traditionally coated onto glass substrates, SwissNeutronics has also developed a super-polishing process to refine the surface of metallic substrates for the coating of neutron supermirrors for highly reproducible large scale fabrication.

About SWISSNEUTRONICS AG

SwissNeutronics was founded in 1999 as a spin-off company from the Paul-Scherrer-Institute (PSI). Today SwissNeutronics is the leading supplier of neutron optical devices based on supermirror technology. With a strong focus on research and development, SwissNeutronics sets benchmarks for the key technologies required for modern neutron scattering equipment. SwissNeutronics products are supplied worldwide to all major neutron research laboratories and cover a wide range of neutron optics as well as the planning, design, construction, and installation of complete instruments. The products are developed and produced by a team of 14 scientists and technicians at the headquarters in Klingnau. SwissNeutronics expertise and capabilities are also provided to industry beyond the field of neutron optics, e.g. functional thin film coatings and 3D metrology.

Dr. Christian Schanzer

Chief Operating Officer

SwissNeutronics AG

Klingnau, Switzerland

christian.schanzer[@]swissneutronics.ch

www.swissneutronics.ch