Nord-lock

2018

Swiss Superbolts Supplied for ITER Fusion Reactor Superstructure

Swiss Nord-Lock AG in St Gallenkappel, Switzerland have supplied specialist bolting solutions for the ITER fusion machine in a multimillion Swiss franc project. Superbolt multi-jackbolt tensioners (MJTs) made from Inconel will be used in the rigid superstructure supporting superconducting magnetic field coils that will confine the ITER plasma particles. The MJTs have been designed to operate under tremendous electromagnetic loads with working temperatures close to absolute zero.

ITER is one of the most ambitious energy projects in the world, a magnetic fusion device to prove the feasibility of fusion as a large-scale and carbon-free source of energy based on the same principle that powers the sun and stars.

Engineers from Nord-Lock AG in St. Gallenkappel, Switzerland have been working on the ITER project for almost ten years alongside thousands of engineers and scientists from the 35 nations contributing to the design of ITER.

Nord-Lock AG provide highly trusted solutions to tough and unusual bolting problems. In 2017, Nord-Lock was awarded a supply contract for Superbolt multi-jackbolt tensioners to the ITER project to be used in the engineering superstructure supporting the high-magnetic field coils.

Superbolts

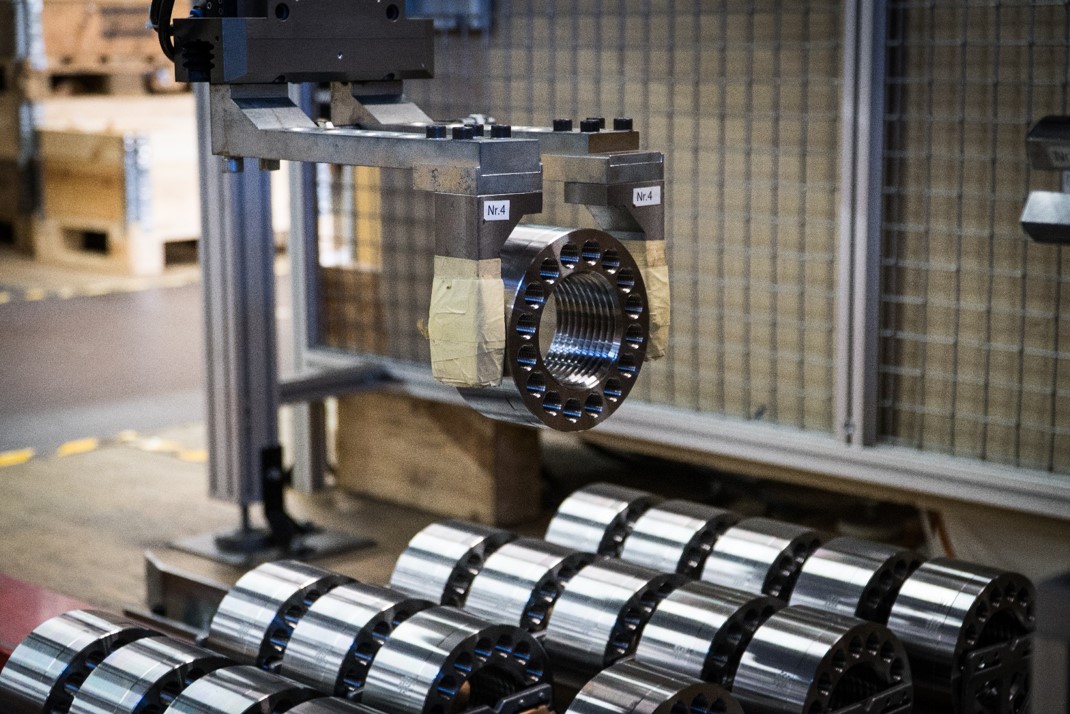

The Superbolt multi-jackbolt tensioners (MJTs) offer an innovative approach to tightening bolts of all sizes. For conventional nuts and bolts the torque needed to tightne a joint exponentially increases as the size increases and often requires heavy tooling and specialist skills.

A multi-jackbolt tensioner takes the high torque requirement in large diameter bolt and breaks it down into manageable torques using a number of smaller jackbolts threaded through the nut body. These can be tightened quicky and easily with ordinary hand tools. MJTs are welle established solution for bolting and are supplied worldwide by Nord-Lock for use in every major industry.

An unusual challenge

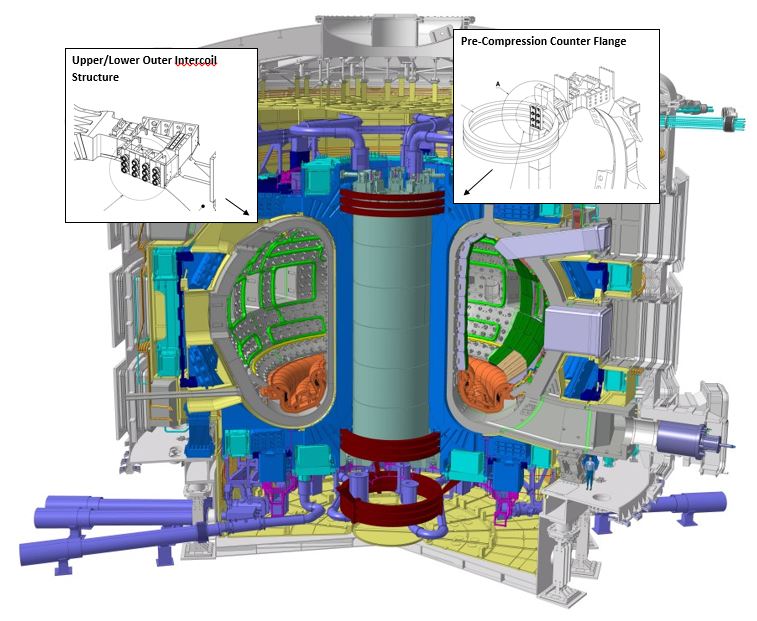

A key component of the ITER project are the 18 D-shaped toroidal field TF coils. These are spaced uniformly around the machine to produce the magnetic field that confines the ITER plasma particles.

The toroidal field coil structures are among the largest and heaviest components of the magnet system, 16 meters high and with a total weight of some 3,400 tonnes. During ITER operation the structure will be subjected to tremendous electromagnetic loads, on the order of tens of thousands of tonnes of force.

The superstructure is designed to resist these forces, with each of the eighteen coils strongly linked between themselves with intercoil structures to support in-plane and out-of-plane forces.

Nord-Lock AG was approached by Japanese engineering companies Toshiba and Mitsubishi to supply MJTs capable of withstanding the operating and cyclic loads inside the ITER machine and working at temperatures around -269°C, close to absolute zero.

Superbolt solution

Nord-Lock MJTs are usually manufactured in normal steel grades, but Nord-Lock opted to use a Inconel steel for the ITER project, due to the exacting operating conditions inside the fusion machine.

Inconel is an austenitic nickel-chromium based super alloy, that does not become brittle, even at very low temperatures. Whilst Inconel is harder and more complicated to manufacture than steel, Nord-Lock has extensive experience working with the material from previous projects.

More than 1000 Superbolt MJTs have been delivered to Japan with a total weight of nearly 30 tons. The tensioners have a main thread of either M80 or M110 and the outer diameter of the biggest tensioner is 220 mm.

Due to the extreme operating environment at ITER, each MJT was subjected to 30 different types of testing and inspections during the manufacturing process to ensure uniformity and conformance with the engineering design.

For a Swiss SME like Nord-Lock, working with ITER has had major benefits. The project has confirmed that Nord-Lock has the engineering expertise to fulfil the most exacting requirements of a large scale scientific facility.

About NORDLOCK AG

Nord-Lock AG manufactures Superbolt® multi-jackbolt tensioners (MJTs) designed to eliminate unsafe and time consuming bolting methods.

MJTs replace or retrofit existing nuts and bolts, and only require hand/air tools for installation and removal of any size tensioner.

As a global leader in bolting solutions, the company offers a unique combination of secure bolting solutions and expertise enabling it to solve the toughest bolting challenges.

Genuine Nord-Lock products are assigned with unique control numbers to ensure full traceability, and multiple quality controls are in place during production. The company has been awarded extensive certifications from independent testing facilities for its commitment to quality.

Nord-Lock Group products are manufactured at state-of-the-art production facilities in Switzerland, Sweden, the United Kingdom, and North America.

Adrian von Däniken

Production Director

Nord-Lock Schweiz AG

Skt. Gallenkappel, Switzerland

adrian.vondaeniken[@]nord-lock.com

www.nord-lock.com