Tiefbohrbär GmbH

2019

Precision Swiss-German consortium manufactures prototype corrugated waveguides for the ITER fusion reactor

The temperature of the gas inside the ITER fusion reactor must reach 150 million degrees Celsius in order to reach the plasma state needed for the fusion reaction to occur.

The fusion reactor will rely on three sources of external heating. One of these is the Electron Cyclotron Resonance Heating system which generates microwave beams at high frequency to initiate each plasma burn, contribute heating power to the plasma, and suppress certain types of plasma instabilities where plasma current is lost and energy content degraded.

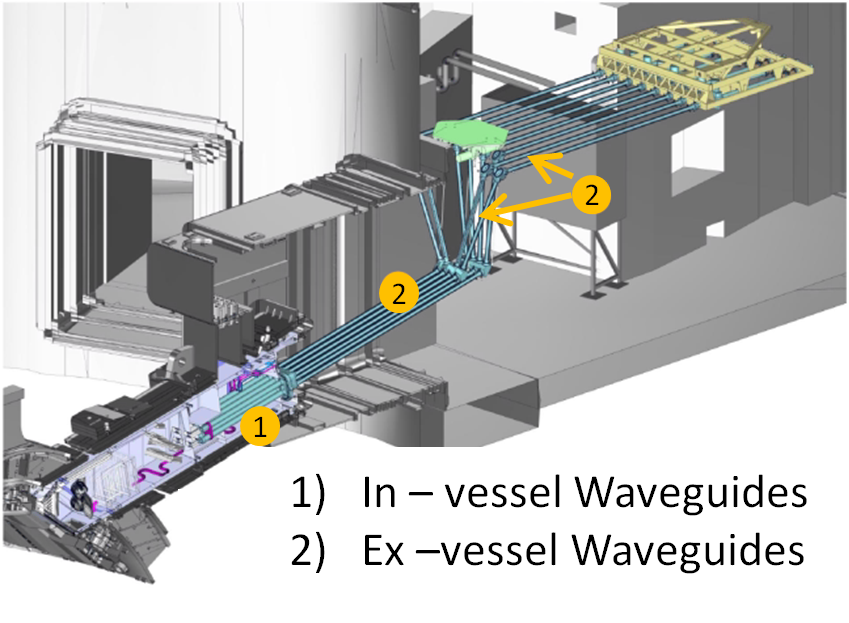

From the Radio Frequency Building where they are generated, the microwave beams travel over 160 meters along waveguides to the fusion reactor, where electron cyclotron launchers deliver them into the plasma at the equatorial and upper levels of the reactor. The waveguide design has a circular cross section with small grooves or corrugations machined into its internal surface that minimize the power transfer losses.

Manufacturing high precision corrugated waveguide prototypes

The waveguide design places strict requirements on material properties, manufacturing process, machining accuracy and assembly constraints. In particular, there are stringent requirements on the perpendicularity of the waveguide connecting flanges relative to the waveguide axis and periodic errors in the internal corrugation pattern must be avoided.

Waveguides with aperture of 50 mm and 120 mm flange have been manufactured with a straightness of 0.2 mm/m on average and 0.05 mm/m near the flanges. The geometry of the inner waveguide surface has a corrugation period of 0.66 mm over lengths of up to 1.7 m. Once completed, the waveguide prototypes are tested at the Swiss Plasma Centre at EPFL Lausanne.

About Tiefbohrbär GmbH

Tiefbohrbär GmbH performs precision deep drilling for high tech applications and is renowned for the smallest, the most unique and the most multifunctional deep drillings in the world.

Deep drilling is the process of drilling deep holes where the drilling depth reaches more than 10 times the drill diameter, and Tiefbohrbär is able to drill deep holes with drilling diameter 0.5 mm to 250 mm up to 6000 mm depth with small tolerances and high quality surface finish. Manufacturing procedures and processes are certified to ISO 9001:2000 and ISO 13485:2003.Deep drilling is the process of drilling deep holes where the drilling depth reaches more than 10 times the drill diameter, and Tiefbohrbär is able to drill deep holes with drilling diameter 0.5 mm to 250 mm up to 6000 mm depth with small tolerances and high quality surface finish. Manufacturing procedures and processes are certified to ISO 9001:2000 and ISO 13485:2003.

With 80 of the newest generation workstations (spindles) the company drills parts for ophthalmology, dental technology, implants and surgery, aerospace, microtechnology, solar energy, machine tools and molds, vehicle and marine engines.

The company was founded in 1996 by skilled toolmaker Markus Bär and his spouse Carmen Bär.

About BGTB GmbH

BGTB GmbH in Dortmund Germany is a consulting company for deep drilling and machining with its main expertise in the development of cutting technology capable of machining non-cylindrical deep holes and chambers in metal parts.

Beat Fankhauser

Project Manager & Sales ITER

Tiefbohrbär GmbH

Lehenweg 15

CH-4852 Rothrist

Switzerland

beat.fankhasuer[@]tiefbohrbaer.com

www.tiefbohrbaer.com